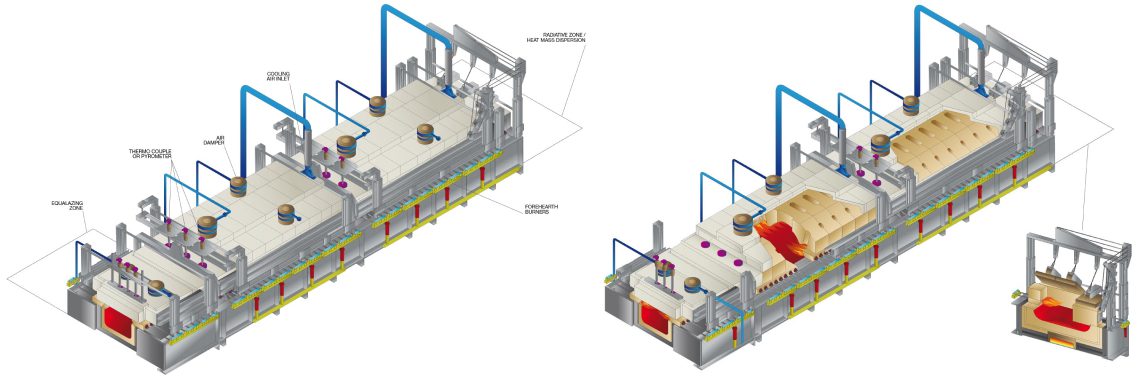

Conditioning working and Forehearth

Technical sheetForehearths designed by the multi-skilled BDF Group are complete with automation and combustion systems specifically developed to achieve such targets with maximum flexibility.

Cooling concept

Very often the energy to be removed from the glass to deliver the required gob temperature is much higher than what is possible to achieve by the dispersion from the refractory and it is necessary, in this case, to implement some additional cooling.

The forced convection cooling system is based on introducing cooling air through the forehearth superstructure. Longitudinal centre line cooling, efficiently removes heat from the hot centre glass without adversely affecting side glass temperatures, and using relatively small volumes of cooling air.

The cover roof design has been developed in order to maximize the refractory surface exposed to the glass in the forehearth centre.

This shape allows increasing the heat exchange between the glass and the cover roof since the glass is exposed to a colder large refractory surface.

The application of this system basically involves the application of openings in the superstructure roof blocks, also used for the combustion waste gases exhaust.

Equipment and accessories for our Forehearth plants

The studies and research developed over recent years combined with cutting-edge design tools are today able to guarantee stability and flexibility in the Furnaces management, for all types of production taking in consideration the strictly environmental regulations of reduction of NOx, SOx and all waste pollution related.

Next step, check our Forming IS Machines

Forming IS Machines