BDF perspective on Hybrid Furnace

A solution followed for the last 6 years with thousands of R&D hours dedicated to it.

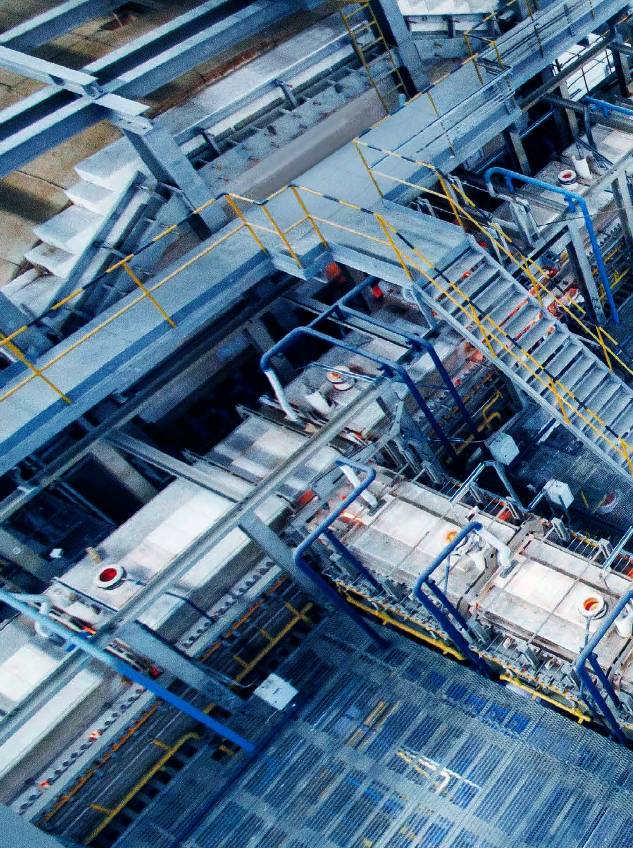

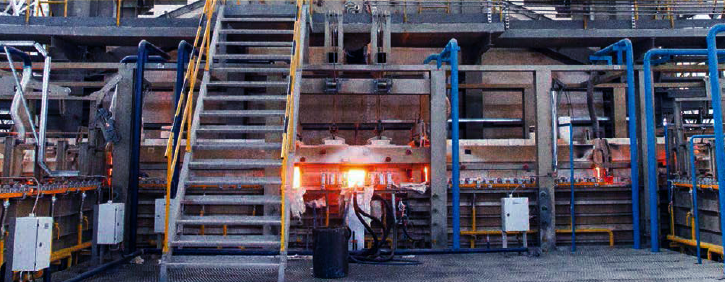

BDF Industries has been founded in 1906 and throughout its long history the Company has focused on covering the entire hot end of the container glass plants. The first BDF Forehearth and is Furnace design is dated back in 1953 and the Automation became a reality in the early 1980s. What makes BDF different from the other suppliers is the merger between the smart engineering needed to face the Glass Melting and Conditioning and the industrial soul that came from over a century of mechanic workshops.

The Context

Nowadays the Glass Melting market is divided into two main demands: the part of the world that pursues the best available technics on the actual arrangement, not linked to emission restriction; and the part that needs to manage in a timely manner how to challenge the emission zero by 2050 therefore must begin to work now towards this goal.

In BDF we are following both paths to claim our position as one of the top suppliers in the present day and keep it, or even increase it, for the future to come. Our strategy is to be focused and keen on Industry 4.0 as a tool to improve performance but also for the diagnostic. Having diagnostic power in these days of innovation can be the game-winning factor to choose between different solutions and technologies. This mission that BDF has is not enough as a strategy for CO2 reduction, we have therefore other technical solutions in our portfolio to present. In this article, we want to spend some words on the Hybrid Furnace concept.

Before the Pandemic, the Container Glass furnaces in the World, considering from 80TPD to 550TPD, are 1163(Glass Global 2019) categorized as follows:

18 (1,5%) fully electric,

31 (2,6%) All Oxygen Melting AOM or oxyfuel,

59 (5%) recuperative furnaces,

196 (16,8%) regenerative cross-fired furnaces,

845 (72,7%) regenerative end-fired furnaces,

14 (1,2%) furnaces made with different technology than above.

This data shows how much we need to move as a whole Industry to leave the furnaces of the past and present to a new era in glass melting. Some groups are switching to Oxyfuel or fully electric to take a little step towards the future to come but remain nevertheless in solutions already proven in the market. The CO2 reduction challenge in Europe set a goal of zero Emissions to be achieved within 2050 with an intermediate step in 2035. Everybody has already said it, but it is important to repeat that is “only 2-3 furnaces away from now”. A common feeling about this ambitious goal is to consider achieving the capacity of the Power Grid Market to supply only green zero CO2 electricity to the grid, at an affordable price, on the same date. This brings to the idea that the All-Electric Melting furnace type can be the ideal solution. The pros of the AEM over the other possibilities are:

AEM is a proven solution present in the market.

AEM is the most efficient Furnace type as per energy consumption.

The CO2 goal is easily achieved given the above assumptions.

Nevertheless, the entire scenario leaves space for certain questions on the OPEX burden of this type of project, the scalability to high pull furnaces, and the possibility to produce reduced glass articles.

It is understandable that cutting out an entire slice of the market as the reduced glass cannot be an uncomplicated way to follow since because it will open a soft spot in the competition with other packaging industries for food and beverage like plastic, aluminium, or paper. Another factor is the electricity cost that can become a limitation for CAPEX and OPEX that oblige the Glass to get away from Europe, and this cannot be good news considering how much this Industry is related to transportation. A wise approach to such a big challenge is always advisable, reaching the target step by step is what BDF sets as a purpose. The hybrid Furnace is the step-by-step solution not only on the main CO2 reduction topic but also to the pull issue of scalability, the flexibility on the OPEX management, and the possibility to manufacture reduced glass.

BDF Solution

The BDF concept presented to various container glass Producers has been developed together with Glass Service Czech Republic and FIC has been modelled and designed for more than 15.000 hours since the first proposal was made back in 2017. We considered 2017 the Hybrid solution as a valid innovative proposal for a customer, totally detached from the CO2 reduction strategy, then this R&D takes progressively the lead in the interest of the Market and consequently in our strategies. We are currently overwhelmed by “hybrid solutions” also in advertising of all-day life: cars, house design, tools etc. therefore, following with decision this project has been a natural behaviour since then. The hybrid furnace is a good compromise step that can lead the way both to total electrification of the melting and remain still open to the development of Hydrogen combustion.

During these years the confrontation and discussion that BDF has had with Glass producers and other players in the Industry, helped us to focus independently on every single small challenge and find a solution that fits even with the overall views. We modelled and designed also solutions based on Air-gas combustion, but this concept resulted in less flexibility in the fuel-boosting switching due to the preheating of the air.

The flexibility on OPEX cost comes from the possibility of oxyfuel combustion to use different ratios of fuel and electricity as the main Melting factor for the glass. The outcome of our experience is that the higher the goal of flexibility higher the more difficulties in design. A good compromise can be about 40-60 / 60-40. The main technical challenge here is the movement of the crown temperature switching between the different melting configurations. BDF is confident in the material research and choice modelled during these years and discussed with the refractory manufacturers. This flexibility is an especially crucial factor for our Market because gives the glass manufacturers the possibility to have control over the production costs and remain competitive in sales, with a distributed benefit for us all in terms of money-saving and sustainability.

The high pull is not a real issue for this type of furnace, and it is also testable from real applications outside the container glass market. One of the fears of the furnace operators is to deal with this heavy bottom boosting and still have a high percentage of cullet, with consequent iron contamination. BDF has a dedicated answer for this concerning the design but also the material choice on this part of the furnace. Different Manufacturers have brought to our attention issues like foaming and redox control, and, therefore, we made little modifications to our design and models. All the knowledge that has been included in our concept makes it a very reliable and production-driven proposal.

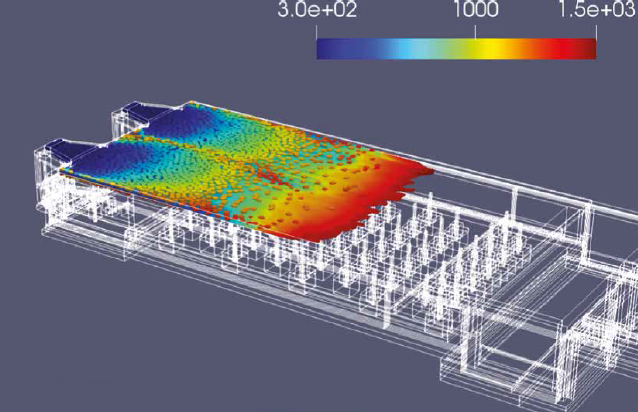

The improvement in the number of the electrode, which can be also more than eighty depending on the furnace size, glass quality, and capacity, is another challenge to manage. Even here BDF has a strategy to reduce the wear and the consequent maintenance load to the lowest. Based on the specific customer application, BDF can tune the Hybrid concept in terms of geometries, electrodes and power distribution, and chemical batch characteristics. Based on the specific input data, a new set of CFD simulations will be prepared and run to validate the final design.

Lastly, we want to state again our focus on high automation and connectivity. Currently, we have developed and used it to give quick and easy remote diagnostic and assistance to our installation, but the future can be paved by the data collecting that this kind of tool can give us to improve the performance and robustness of our Furnaces.

To Sum Up

In conclusion, our recipe for the future is reliable and solid. It is based on remarkably high automation and digital improvement as a sustain to the CO2 reduction solution in our portfolio. The main goal is the Hybrid Furnace but we have a solution also on the conditioning zone with full electric forehearth without electrodes in contact with the glass, in the combustion system, and the Forming line. If you are interested, we warmly recommend you contact your local BDF Area Manager. BDF is not new to this container glass market’s innovative approach as proven by its history. The path is now traced, we wait for you to join us and follow it, the future is on stack, and we have a map to reach the target.