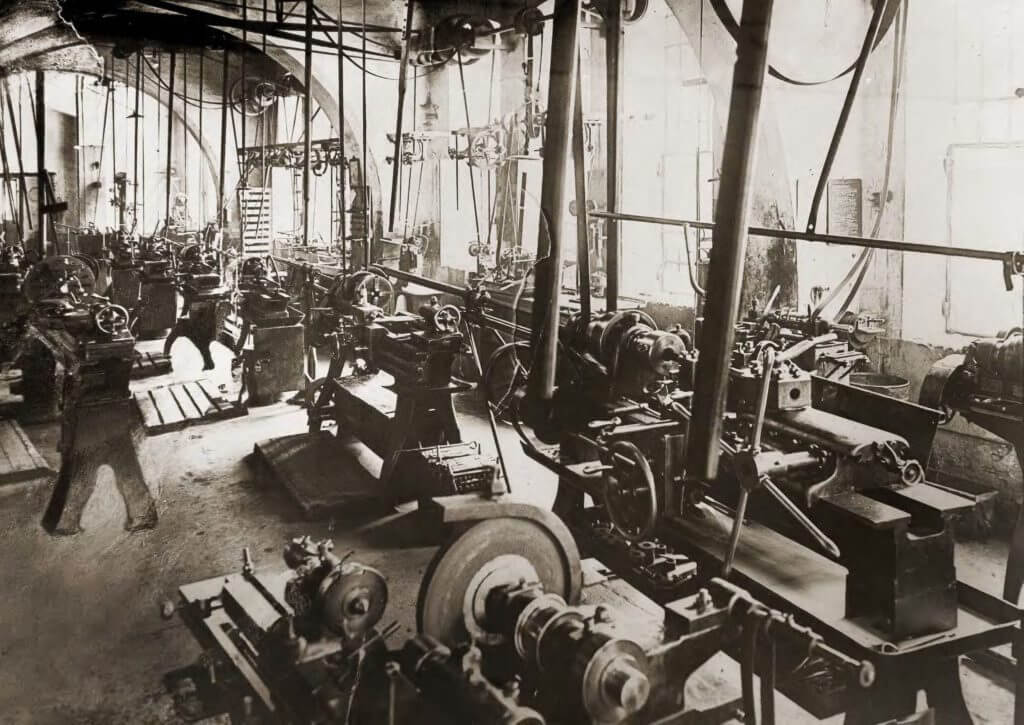

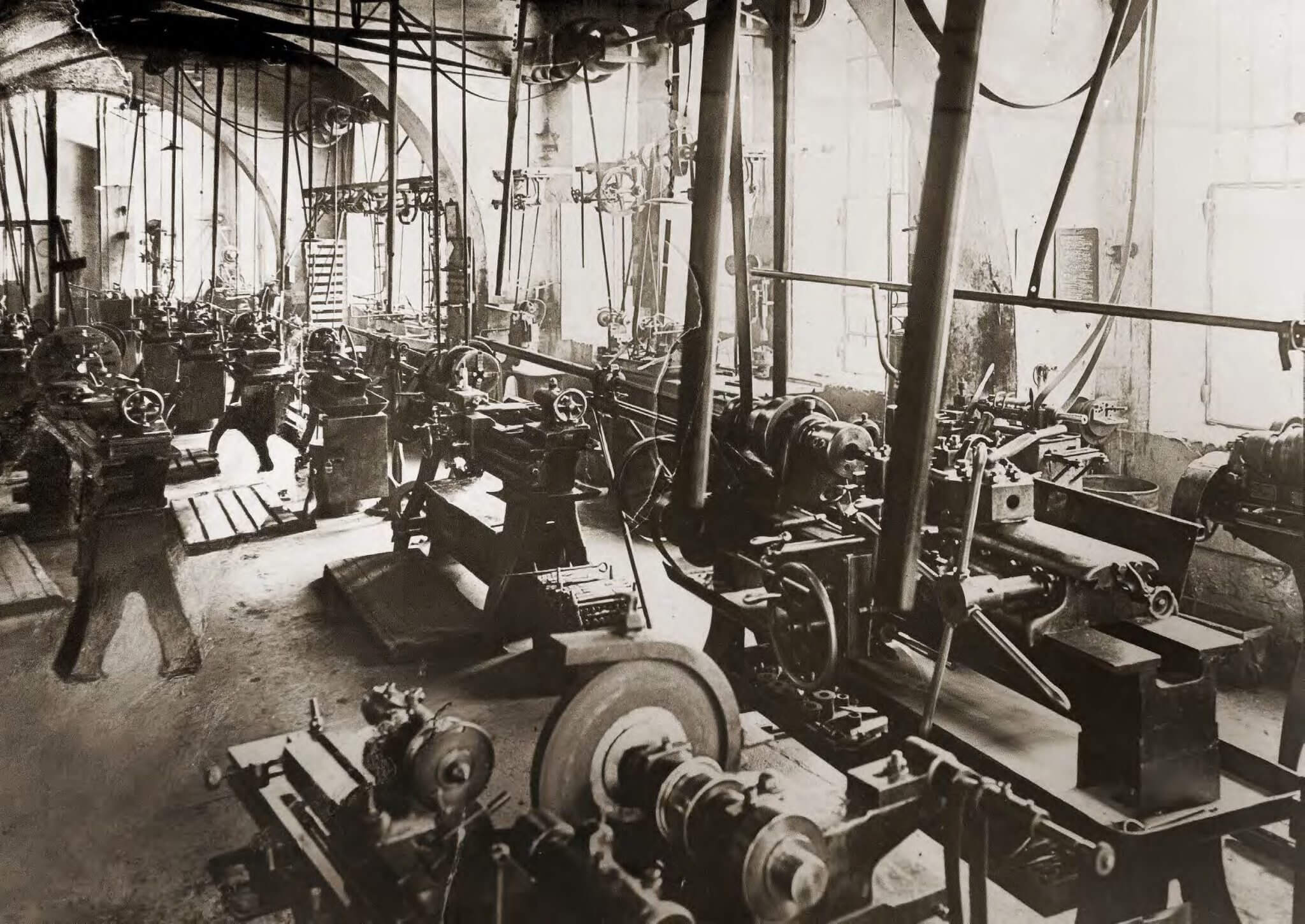

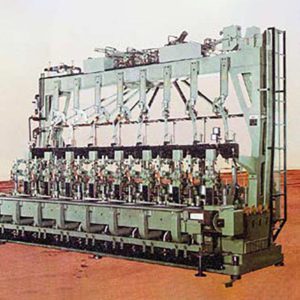

BDF Industries is a manufacturer of technologically advanced machinery where performance and innovation melt together in an everlasting pursuit of excellence.

We are an International Group whose focus and mission are to innovate and bring our products anywhere in the World.

We design and build our complex machines with passion, giving safety and quality the highest priority while combining engineering skills with technological research. Our purpose is to go beyond standards and think «out of the box», to continue to satisfying our customers’ needs in terms of performance and services.

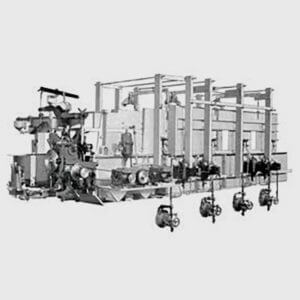

We offer the best plants and equipment solutions serving various markets such as food & beverages, perfumery, cosmetics and pharmaceuticals. The plants are studied to ensure high performances and designed in accordance with customer specifications.

Find out more about BDF Industries

More about our services More about our R&D department