Our daily commitment is to help transform any opportunity into customer success

We have dedicated our energies, skills and determination to make BDF Customer Service a valued, integrated part of our company.

To make sure that we can always reach our customer high satisfaction levels, the Customer Care Service has been included as part of the company’s overall approach to continuous improvement.

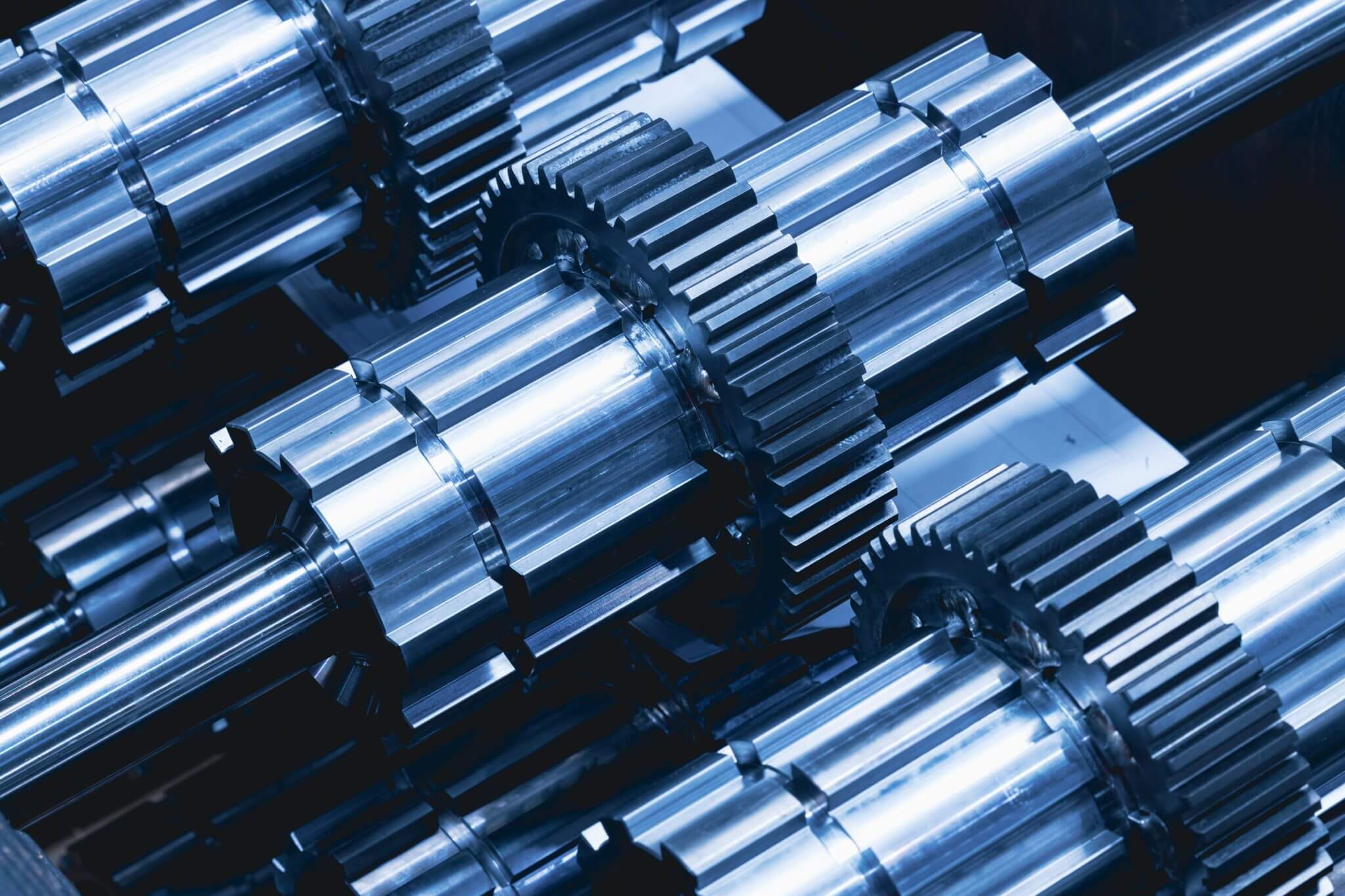

Spare parts

Over 40,000 parts ready for you, to complete a correct maintenance routine. Our Customer Care Department can help you to planning the perfect maintenance schedule, with all the necessary spare parts for your plant and machines to operate at the best performance levels.

Pre-sale Services

Supervised installation

A team of skilled technicians travels the world to supervise and co-ordinate the set up of the machines supplied to make sure that they will be ready to produce glass containers as soon as possible.

Trainings

We offer practical training programs for planning, maintenance and product use to enable you to exploit the full potential of your BDF machine or system. We constantly refine and update our courses with the support of qualified instructors, trained to give you the most up-to-date instructions, both theoretical and practical. We are able to provide trainings at BDF HQ or on site at your plant.

Technical assistance

Maintenance or repair

All equipment requires scheduled maintenance or repairs. Depending on the nature of the repair and the size of your equipment, BDF offers onsite repair, assistance and online assistance. You will have at disposal a complete range of services for equipment maintenance, overhaul and testing to restore equipment to the original operating condition.

Preventive Maintenance

In our Industry it is important to prevent problems and bugs, it is crucial in terms of safety and profit as well. For this reason we suggest you to trust BDF Customer Care Team in order to arrange the best schedule concerning spare parts and technical assistance.

Turnkey solutions

The turnkey solution might be the best option to give a boost to your operations workflow. We can offer a cost-effective solution for various business processes, guaranteeing the fastest way to start your glass plant.

Why to choose our onsite assistance

Minimised downtime by fast, reliable onsite repair services at customer facility

Highly qualified BDF service engineers and technicians from BDF HQ

Time and cost-effective way to resolve problems related to unexpected issues

Backed by a solid BDF warranty

Convenient pick-up and delivery services thanks to an efficient Shipping Department

Supervision to installation and production start-up