Timing System

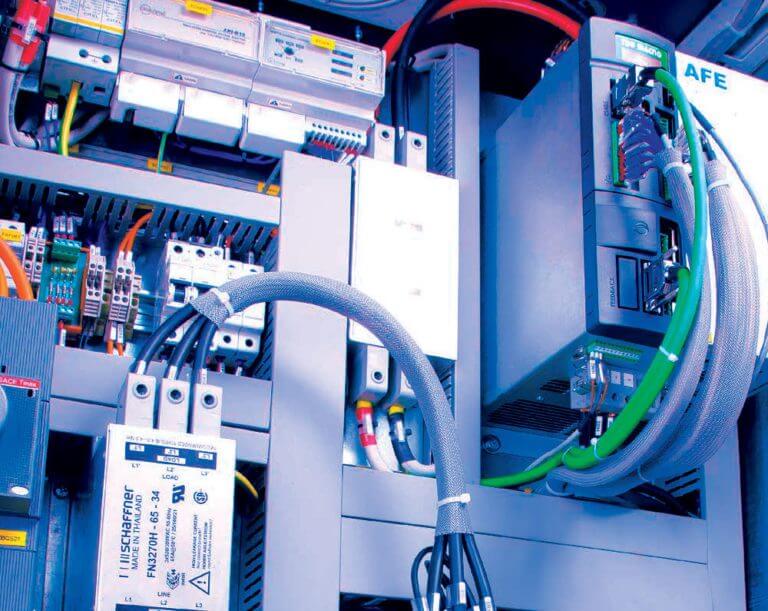

Accessories & Equipment for IS Machines

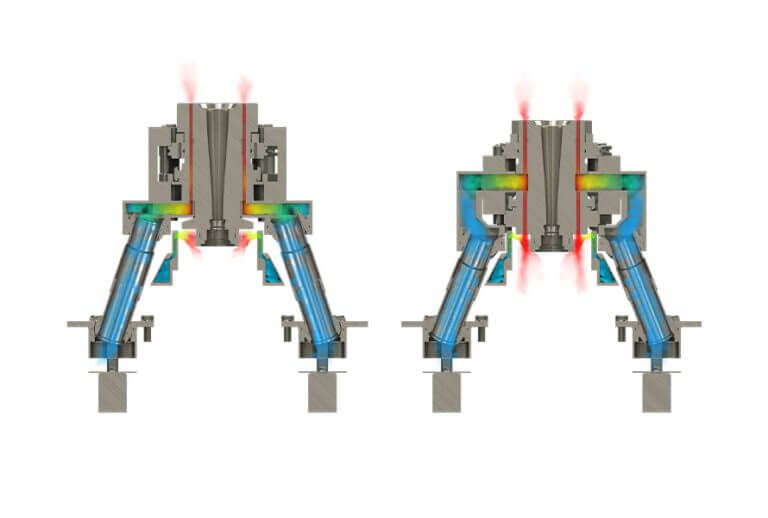

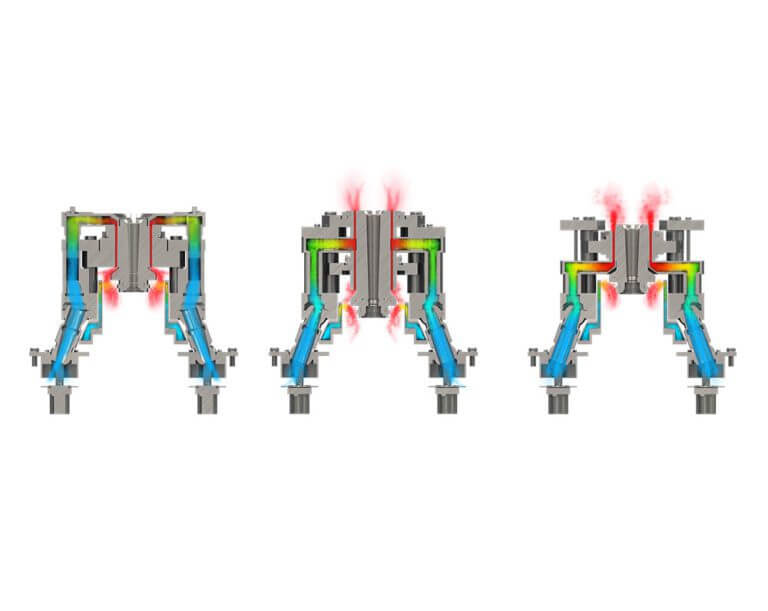

Blank and blow bidirectional axial cooling, down-up blank axial cooling, blank top-down axial cooling, blank down-up axial cooling, blank and blow bidirectional axial cooling, ADV series, AFE and more.